Bio-mimicking

Extrinsic Self-Healing Asphalt Technology seeks to enable material systems to heal after damage and to extend or to renew the functionality and life-time of the damaged part, system or device. There are four different extrinsic self-healing systems for asphalt pavements:

Induction Heating

Involves adding electrically conductive fillers (steel fibres and steel wool) into the asphalt mix and initiates healing by sending an alternating current through the coil. When the conductive asphalt specimen is placed beneath the coil for 3-5 minutes, the electromagnetic field induces currents flowing along the conductive loops within the asphalt formed by steel fibres. The current causes the conductive particles – steel fibres or iron powder – within the asphalt to heat, the heat softens the bitumen allowing it to flow, thereby sealing the cracks and repairing the damaged asphalt.

Microwave Heating

Creates high-energy wavelengths which react to the conductive particles in the asphalt. As with induction heating, microwave heating causes the conductive particles (steel fibres) embedded in the bitumen mix, to heat up. The heat causes the aged bitumen to soften, allowing it to flow and repair the micro crack damage. Laboratory studies have shown that this method can repair test specimen damage within 3 minutes of heating. The microwave method requires fewer conductive fibres to achieve the temperature required for healing to occur. Researchers have demonstrated that the induction and microwave heating methods are efficient methods for healing asphalt damage in comparison to rejuvenation. However, a challenge with both methods is that the heating process (both induction and microwave) ages the bitumen, causing binder brittleness and the premature failure of the asphalt.

Rejuvenator Encapsulations

Method was developed to address the challenge of bitumen ageing caused by induction and microwave heating (1, 2 above). Rejuvenation involves adding an encapsulated healing agent (rejuvenator) into the asphalt mix to restore the original bitumen properties. When micro-cracks form within the pavement, they encounter a capsule. The fracture energy at the tip of the propagating crack opens the capsule, releasing the healing agent which then diffuses within the bitumen to seal the crack. The rejuvenator encapsulation approach represents a more favourable method of asphalt self-healing as it enables the aged bitumen to return to its original chemical, physical and mechanical properties. However, there are limitations with this method of self-healing because the healing rate is slow and healing efficiency low.

Hybrid (Combined) healing

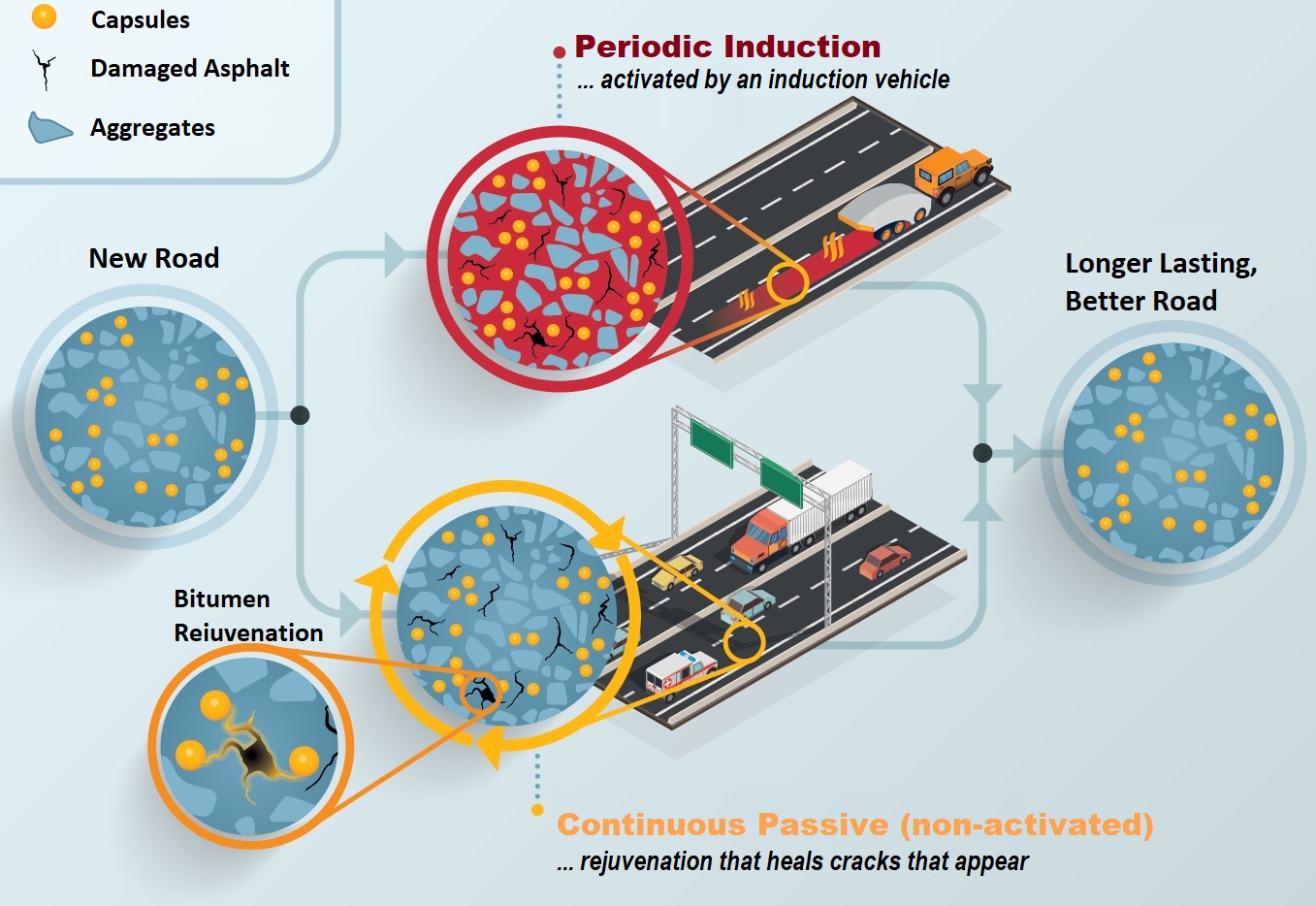

Provide a solution to the challenges associated with induction, microwave and encapsulated rejuvenation (methods 1-3 above). Hybrid self-healing technology combines induction heating and encapsulated rejuvenation. In this process, induction heating is used to repair the asphalt damage (and close the cracks) while rejuvenation is used to replenish the aged asphalt binder (bitumen).

The idea of the extrinsic self-healing for asphalt pavements (roads) stems from the concept of the “forever open road”, motivated by the need to avoid the traffic disruption (and associated risk of accidents) caused by road maintenance activities on busy roads. A challenge for the road industry is how to ensure the safety of road construction workers during the pandemic (keeping them safe from COVID-19 as well as from road traffic). How can road construction workers/crews maintain social distancing from each other and from vehicle, cyclist and pedestrian traffic while also remaining safe from oncoming traffic. In the UK, 175 crashes per month are caused by drivers driving into road-work sites. The USA Centre for Construction Research and Training (CPWR) reported 1,230 fatalities and 324,000 work zone injuries of road construction workers between 2009 and 2018. These figures show that current methods of road maintenance involve risk and danger for road maintenance workers/crews. Extrinsic self-healing asphalt technology has the potential to reduce the need for road maintenance, thereby reducing risk to road maintenance workers while simultaneously reducing the environmental impact of road construction. It is estimated that extrinsic self-healing asphalt technology could reduce energy consumption and CO2 emissions by 30% over the lifetime of the road. Extrinsic self-healing asphalt technology has potential to address several of the technical, economic, environmental and safety challenges currently facing the road industry.